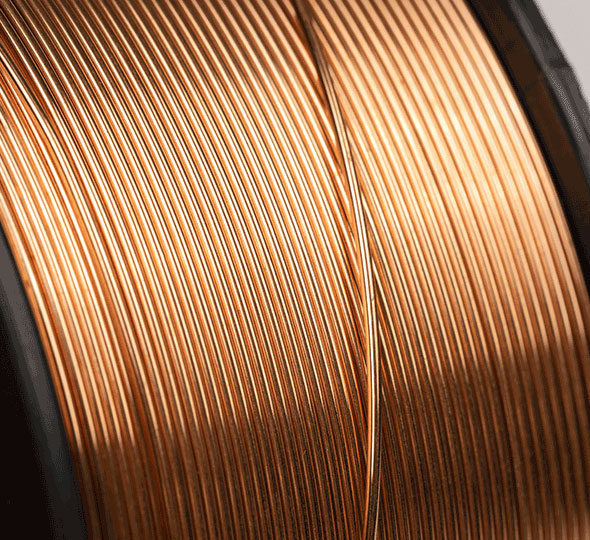

Submerged Arc Welding Wire EM13K

Our welding materials products consist of three major series: solid welding wires, flux-cored welding wires, and welding electrodes, with over 200 varieties in total. In addition to their conventional applications, our products are also evolving towards specialized welding materials for high-strength steel, heat-resistant steel, stainless steel, and non-ferrous metals. These welding materials are widely used in various industries, including steel structure construction, shipbuilding, pressure vessels, oil pipelines, rail transit, marine engineering, and nuclear power.

Specification parameters

Product specifications

Conformance

AWS: EM13K

Typical Application

Using with sintered flux SJ101

Applied both for high-speed welding steel plate of tensile strength 420MPa and filling welding.

Mechanical Properties

| Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Impact Energy (J) | Impact Temperature (°C) |

| 490~670 | ≥390 | ≥18 | ≥27 | -20 |

Chemical Composition %

| C | Mn | Si | S | P | Ni | Cr | Cu |

| 0.089 | 0.98 | 0.67 | 0.023 | 0.032 | 0.034 | 0.015 | 0.11 |

Reference

| Flux | SJ101 | |||

| Diameter (mm) | 2.5 | 3.2 | 4 | 5 |

Submerged Arc Welding Wire EM13K Description

Welding is a fundamental process in the construction of various heavy machinery, infrastructure, and transportation systems. Among the many welding electrodes available today, the carbon steel welding electrode E7016 stands out as a highly reliable and efficient choice for critical applications requiring high-strength joints. Known for its robustness, durability, and versatility, the E7016 welding electrode is extensively used for welding carbon steels and low alloy steels, making it an indispensable tool in the construction of ships, vehicles, buildings, and bridges.

Longteng proudly presents its high-performance EM13K Submerged Arc Welding Wire, a superior solution designed for exceptional weld quality, operational efficiency, and consistent mechanical properties. As a dedicated SAW welding wire exporter, Longteng has established a strong reputation for providing advanced welding consumables that meet the demanding standards of industries worldwide. The EM13K welding wire stands out for its reliability, adaptability, and quality, ensuring seamless welding performance across various applications.

Exceptional Design and Composition

The EM13K welding wire is a medium-manganese, medium-silicon, low-carbon steel wire, engineered specifically for submerged arc welding (SAW) applications. Its chemical composition has been meticulously balanced to ensure optimal performance in both single- and multi-pass welds. With excellent arc stability and slag removal characteristics, the wire is suitable for welding in automated, semi-automated, and mechanized systems.

Designed for use with neutral or slightly basic fluxes, the EM13K wire delivers high-quality weld metal with good impact toughness and tensile strength. The consistent diameter and surface quality of the wire ensure smooth feeding and stable arc characteristics, which are critical in maintaining the integrity of the welding process.

Superior Welding Performance

Longteng’s EM13K SAW welding wire is renowned for its excellent welding performance, particularly in structural steel, pressure vessels, and shipbuilding applications. It provides a smooth and uniform bead appearance, low spatter levels, and superior penetration, which reduces the need for extensive post-weld cleaning or grinding.

The EM13K welding wire also offers outstanding weld metal ductility and toughness, even in low-temperature environments. This makes it a preferred choice for heavy-duty fabrication where structural integrity is paramount. Its compatibility with various SAW fluxes adds to its versatility, ensuring that it can be used in a broad range of industrial welding scenarios.

Applications Across Multiple Industries

As a globally recognized SAW welding wire exporter, Longteng caters to multiple industries where strength, durability, and precision are critical. The EM13K submerged arc welding wire is ideal for:

Structural steel fabrication

Shipbuilding and marine structures

Offshore platforms and oil rigs

Pressure vessels and boilers

Bridges and heavy equipment manufacturing

Its robust performance makes it a dependable solution for industries that demand not only strong mechanical properties but also efficiency and consistency in large-scale welding operations.

High-Quality Manufacturing Standards

All EM13K welding wires produced by Longteng undergo rigorous quality control throughout the manufacturing process. Starting from the selection of raw materials to the final inspection, every step adheres to international quality management systems. The wires are precision-drawn, copper-coated for corrosion resistance, and meticulously spooled to prevent tangling during usage.

Our advanced production facilities utilize state-of-the-art technologies to maintain tight dimensional tolerances and consistent chemical properties, ensuring that every spool of EM13K SAW welding wire performs reliably in the field.

Packaging and Export Expertise

As a leading SAW welding wire exporter, Longteng places significant emphasis on secure and efficient packaging. EM13K wires are available in various spool sizes and packaging formats to meet the diverse needs of our clients. Whether for bulk industrial use or customized orders, our packaging ensures the wire remains clean, dry, and free from contaminants.

Our logistics and export departments are experienced in managing large-scale international shipments, ensuring timely delivery and compliance with export regulations. Longteng supports its customers with documentation, technical data sheets, and assistance throughout the supply chain.

Environmental Responsibility and Safety Compliance

Longteng is committed to environmental sustainability and workplace safety. The EM13K submerged arc welding wire is manufactured using eco-friendly processes that minimize emissions and waste. We also ensure compliance with global safety standards, providing a safe and efficient product for operators and industrial use alike.

Proper storage and handling instructions accompany each shipment to maintain product integrity and ensure a safe working environment. The wire is engineered for stable arc performance, reducing fume generation and contributing to a healthier welding workspace.

Customization and Technical Support

Recognizing that each project has unique requirements, Longteng offers customization options for the EM13K SAW welding wire. Whether it’s tailored chemical composition, packaging format, or technical assistance during deployment, our team of engineers and product specialists are ready to collaborate with clients for optimal results.

Our technical support includes weld procedure consultation, troubleshooting, and guidance on flux-wire combinations to enhance performance. This customer-first approach strengthens Longteng’s position as a trusted SAW welding wire exporter and partner in industrial innovation.

Why Choose Longteng’s EM13K SAW Welding Wire?

Choosing Longteng’s EM13K submerged arc welding wire means selecting a product that embodies quality, reliability, and industry expertise. Our decades of experience in manufacturing and exporting welding consumables have made us a preferred supplier to clients around the globe. The advantages of our EM13K wire include:

High deposition rates for increased productivity

Excellent bead appearance and mechanical properties

Reliable performance in both automatic and semi-automatic welding

Consistency in chemical and physical properties

Expert technical support and customization options

Global shipping capabilities and efficient delivery

A Benchmark in SAW Welding Wire Solutions

The EM13K submerged arc welding wire from Longteng represents a synthesis of advanced metallurgy, practical performance, and global service. As a premier SAW welding wire exporter, Longteng is dedicated to pushing the boundaries of what welding consumables can offer in modern industry. With a commitment to quality, customer satisfaction, and technological progress, the EM13K wire sets a new benchmark for submerged arc welding applications.

Partner with Longteng today and experience the difference of working with a leading name in welding solutions. Let the EM13K SAW welding wire be the foundation of your next successful project.

Market applications

Cooperative partner

Longteng Special Steel actively seek industry cooperation, jointly promote industry progress and dev

Product certification

Certified by seven classification societies

Certified by seven classification societiesOur company's products have been recognized by China Classification Society, Det Norske Veritas, American Bureau of Shipping, Lloyd's Register, Nippon Kaiji Kyoka, Bureau Veritas, and Korean Register of Shipping. Additionally, they have also passed TÜV, DB, CE certifications, as well as the Canadian Welding Bureau (CWB) certification for steel structures.

Intelligent production

Intelligent productionAdopting intelligent automated production lines, through process innovation and improvement, a green and efficient production model is achieved.

The whole industry chain has stable and reliable quality

The whole industry chain has stable and reliable qualityWe can customize suitable products according to customer requirements and provide on-site welding guidance.

Complete specifications, timely delivery

Complete specifications, timely deliveryFull series production, L200×90~L450×125, complete varieties.

Provide excellent after-sales service methods and strategies

- Establish a comprehensive after-sales service system, cultivate a professional after-sales service team, and continuously improve the quality of after-sales service

- 7 * 24-hour timely response to customer needs

- Professional engineers provide personalized solutions

- Having professional technical means to improve after-sales service efficiency

+8613773095803

Email

Email