Why Inverted Angle Steel is Key to Strength and Durability in Marine Engineering and Shipbuilding

2025-07-30

In marine engineering and shipbuilding, materials play a critical role in the safety, performance, and durability of vessels and offshore structures. Among the many types of structural steel used in these industries,inverted angle steel stands out as a versatile and highly effective choice. This type of steel is used in various applications, from the construction of ships to offshore oil platforms, thanks to its unique properties and ability to provide robust support in challenging marine environments. In this article, Longteng will explore the importance of inverted angle steel in marine engineering and shipbuilding, focusing on its applications, benefits, and the key factors that make it a preferred material in these industries.

What is Inverted Angle Steel?

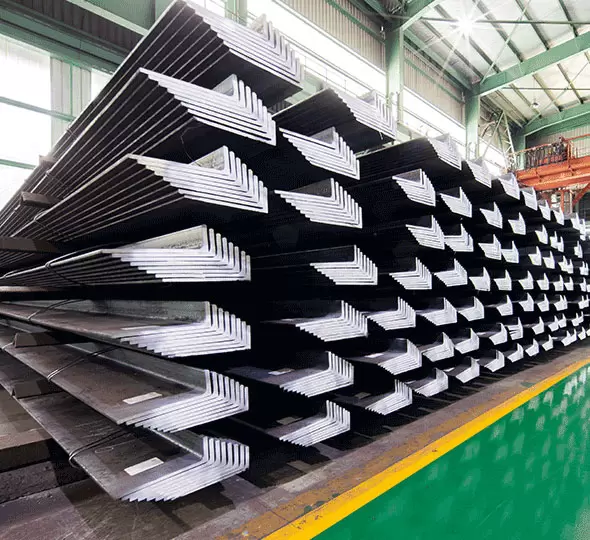

Inverted angle steel refers to a type of structural steel with an "L" shape, but with the vertical leg positioned at the bottom, unlike traditional angle steel where the legs are aligned in a standard "L" orientation. This specific orientation gives the steel unique properties that make it suitable for various applications, especially in marine engineering and shipbuilding.

The inverted angle shape allows for better resistance to bending, offering improved structural stability, particularly in areas where stress and strain are prevalent. The design also enhances load-bearing capacity, making it ideal for situations where steel needs to support heavy weights and endure harsh environmental conditions.

In marine engineering and shipbuilding,inverted angle steel is often used in the construction of hulls, decks, supports, and other critical components of ships and offshore platforms.

Applications of Inverted Angle Steel in Marine Engineering

Marine engineering involves the design, construction, and maintenance of ships, submarines, and offshore structures. In this field,inverted angle steel is extensively used for several important reasons. Here are some of the primary applications of inverted angle steel in marine engineering:

1.Ship Hull Construction

The hull of a ship is its main structural component, designed to withstand the pressures and stresses of water and harsh sea environments.Inverted angle steel is commonly used in the fabrication of ship hulls, particularly in the framing and bracing structures. The inverted design of the angle steel allows it to handle the immense weight and forces that occur during the ship's voyage, making it highly durable.

The robust properties ofinverted angle steel help prevent deformation and ensure the hull remains intact during rough seas. The material's ability to resist bending and twisting adds to the overall stability and safety of the ship. This makes inverted angle steel a crucial part of a ship's structural integrity.

2.Offshore Platform Construction

Offshore platforms, such as oil rigs and floating production units, require materials that can withstand extreme environmental conditions, including saltwater corrosion, high winds, and heavy operational loads.Inverted angle steel is ideal for the construction of these platforms, where its superior load-bearing capacity and resistance to stress are essential.

In offshore platform construction,inverted angle steel is commonly used for the structural support of beams, columns, and other critical components. The inverted angle design provides added strength, which is especially beneficial when supporting large equipment and machinery. Moreover,inverted angle steel ensures a more stable foundation for the platform, contributing to its overall safety and reliability.

3.Ship Decks and Superstructures

Ship decks and superstructures must be able to support the weight of various equipment and withstand constant exposure to the elements.Inverted angle steel is widely used in the construction of these parts of the ship because it offers excellent stability and strength. Whether used in the framing or as part of the overall support system, inverted angle steel ensures that the ship's upper structure remains intact even in challenging conditions.

The material's ability to resist bending and corrosion ensures that the decks and superstructures of ships maintain their structural integrity over time, even with the constant exposure to water, salt, and wind. This makesinverted angle steel an essential material for the longevity and safety of ships.

4.Shipbuilding Supports and Frames

In shipbuilding, the overall framework of a vessel is supported by a series of frames and structural members.Inverted angle steel is often used for these critical support structures. Due to its ability to handle large loads without bending, it is perfect for use in frames that are subjected to intense forces, such as those experienced by ships in motion.

Additionally, the design ofinverted angle steel helps reduce the amount of material needed while maintaining structural strength. This makes it an efficient choice for shipbuilders who need to balance strength with cost-effectiveness.

Benefits of Inverted Angle Steel in Marine Engineering

The use ofinverted angle steel in marine engineering and shipbuilding offers several significant benefits. Below are the key advantages that make it the material of choice for these industries:

1.Improved Load-Bearing Capacity

One of the key advantages of inverted angle steel is its exceptional load-bearing capacity, which makes it ideal for the demanding requirements of marine engineering and shipbuilding. The unique inverted design of the steel allows for more efficient distribution of forces, ensuring that the material can withstand heavy loads encountered during operation. This makes inverted angle steel a preferred choice for critical structural elements such as the hull, deck, and frame of ships and offshore platforms.

The load distribution of inverted angle steel not only improves its strength but also enhances the overall structural integrity of marine vessels. By optimizing the material's ability to absorb and distribute stresses, it ensures that the structure remains stable even in the face of external forces, such as waves and rough weather conditions. As a result, ships and offshore platforms made with inverted angle steel experience greater durability and performance over time, reducing the risk of failure under heavy load conditions.

2.Enhanced Structural Stability

The design of inverted angle steel provides enhanced structural stability, an essential factor in marine environments. The shape of the steel—an inverted "L" or "V"—gives it significant resistance to bending and warping, even when subjected to the dynamic forces of wind, waves, and water pressure. This stability is crucial for maintaining the integrity of marine structures like ships and offshore platforms, which must endure constant stress throughout their service life.By using inverted angle steel, marine engineers can significantly reduce the risk of structural deformation, which is especially important for maintaining the safety and operability of vessels. The material's ability to resist bending and twisting helps prevent the weakening of key structural components, ensuring that the vessel maintains its performance and lifespan in challenging conditions. Furthermore,inverted angle steel's stability also minimizes the need for frequent repairs and replacements, leading to more reliable and long-lasting marine structures.

3. Corrosion Resistance

In marine environments, exposure to saltwater and harsh weather conditions makes corrosion resistance a top priority for materials used in shipbuilding and offshore platform construction.Inverted angle steel stands out in this regard due to its inherent resistance to corrosion, especially when made from high-quality alloys or treated with protective coatings. This makes it an ideal choice for applications where materials are in constant contact with saltwater, such as the hulls of ships and supports for offshore rigs.

By using inverted angle steel, marine engineers can significantly extend the life of a structure, reducing the frequency of repairs and replacements due to corrosion. Additionally,inverted angle steel's resistance to rust and corrosion ensures that the structural integrity of marine vessels is maintained, even when exposed to the aggressive effects of marine environments. This not only helps ensure safety but also reduces long-term maintenance costs, making it a cost-effective material for marine engineering projects.

4. Cost-Effectiveness

Inverted angle steel offers a highly cost-effective solution for marine engineering and shipbuilding projects. Its high strength-to-weight ratio means that less material is required to achieve the same level of structural integrity compared to other materials. This reduction in material requirements leads to savings in both material and labor costs, making inverted angle steel an economically attractive option for large-scale construction projects like ships and offshore platforms.

Furthermore, the durability of inverted angle steel reduces the need for frequent maintenance and repairs, offering long-term cost savings. Since inverted angle steel resists corrosion and deformation, the cost of upkeep and repair is lower, making it a reliable material choice for shipbuilders and marine engineers looking to minimize lifecycle costs. Ultimately,inverted angle steel provides a solid balance between performance, cost, and longevity, making it a smart investment for the marine industry.

5.Versatility in Application

The versatility of inverted angle steel makes it suitable for a wide range of applications in both shipbuilding and offshore platform construction. From the structural framework of a vessel to support beams and columns in offshore platforms,inverted angle steel can be used in various critical parts of a marine structure. Its adaptability allows it to be incorporated into diverse designs, making it an essential material for optimizing the structural integrity of ships and offshore rigs. Whether used for the hull, deck, or internal support structures,inverted angle steel offers flexibility in design while maintaining strength and stability. Marine engineers can rely on this material to meet the specific demands of each project, whether it's ensuring the strength of a vessel's framework or providing reliable support for offshore operations. The flexibility of inverted angle steel in different applications also allows engineers to streamline the construction process, reducing both complexity and cost.

Inverted angle steel is a crucial material in marine engineering and shipbuilding, offering numerous advantages in terms of strength, stability, corrosion resistance, and cost-effectiveness. Its versatility in applications such as ship hulls, offshore platforms, decks, and frames makes it an essential component in the construction of safe and durable marine structures. As the demands on the marine industry continue to grow,inverted angle steel remains a reliable and efficient choice for ensuring the longevity and safety of ships and offshore platforms.

Email

Email