The Power of Carbon Steel Welding Electrode E7016 in Heavy-Duty Applications

2025-05-29

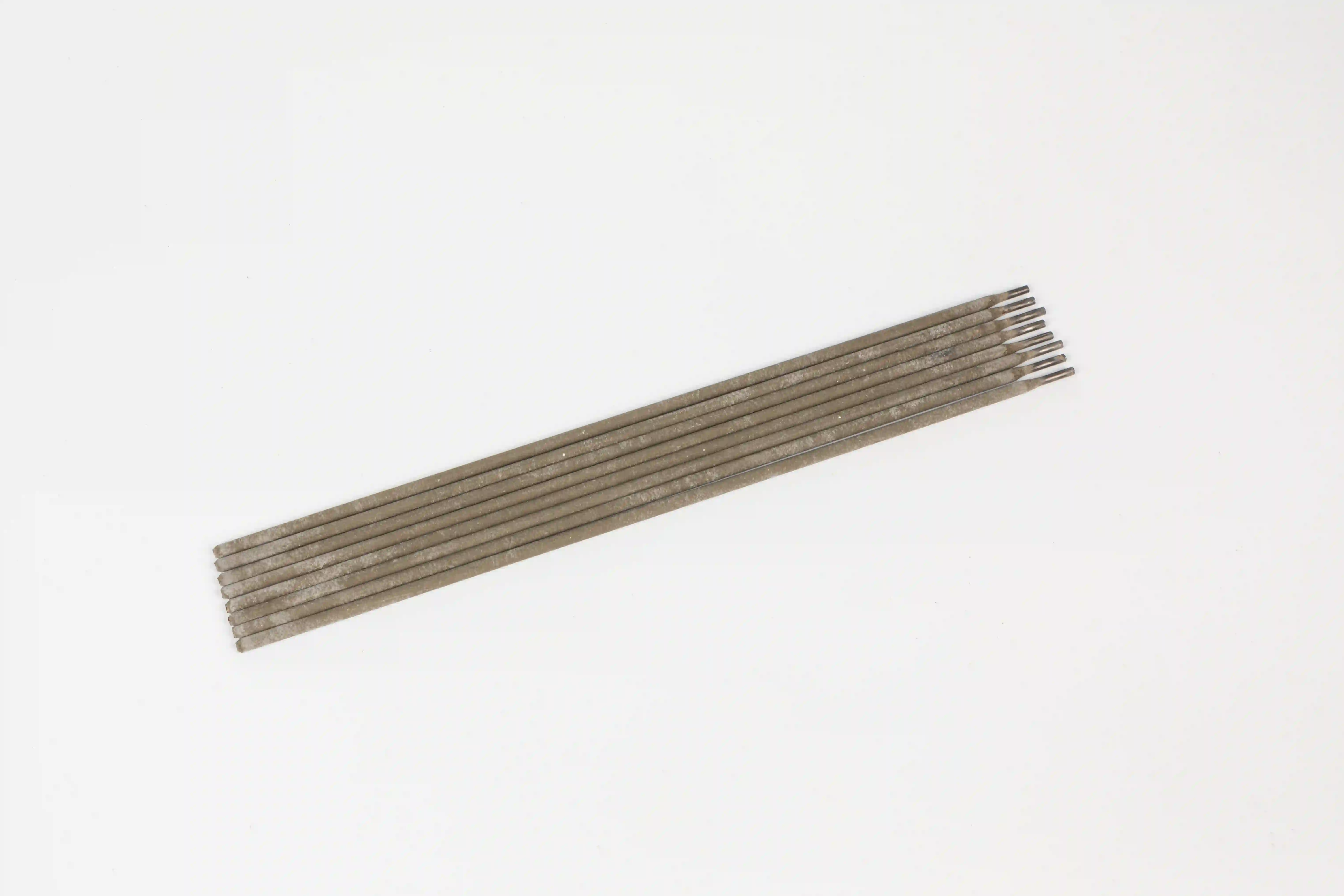

Welding is a fundamental process in the construction of various heavy machinery, infrastructure, and transportation systems. Among the many welding electrodes available today, the carbon steel welding electrode E7016 stands out as a highly reliable and efficient choice for critical applications requiring high-strength joints. Known for its robustness, durability, and versatility, the E7016 welding electrode is extensively used for welding carbon steels and low alloy steels, making it an indispensable tool in the construction of ships, vehicles, buildings, and bridges. This article explores the key features of Longteng carbon steel welding electrode E7016, detailing its importance in welding high-strength components that are fundamental for the construction of infrastructure and machinery that withstand harsh conditions and heavy usage.

What is Carbon Steel Welding Electrode E7016?

The carbon steel welding electrode E7016 is a type of coated electrode used in the shielded metal arc welding (SMAW) process. It is known for its versatility, high-strength welds, and excellent performance across a variety of applications, particularly in welding low alloy and carbon steels. The E7016 designation refers to specific properties of the electrode, as per the American Welding Society (AWS) standards.

The first two digits, "70," indicate that the electrode has a minimum tensile strength of 70,000 psi (approximately 485 MPa). The "1" in the third digit signifies that it is suitable for welding in all positions, and the "6" in the last digit denotes that the electrode has a high cellulose potassium coating, which provides a smooth, stable arc and good arc shielding in challenging welding conditions.

Longteng carbon steel welding electrode E7016 is designed specifically for welding high-strength steel structures, such as the frames of ships, construction vehicles, buildings, and bridges. It is particularly effective in welding A, B, C, D, and E-grade steel materials, which are commonly used in heavy-duty construction and manufacturing applications.

Key Features of Longteng Carbon Steel Welding Electrode E7016

1. High Tensile Strength

One of the primary reasons the carbon steel welding electrode E7016 is favored for industrial applications is its high tensile strength. With a tensile strength rating of 550 MPa, it is capable of producing welds that can withstand heavy loads and stresses. This property is crucial for projects where the welded materials are exposed to mechanical forces and require strong, reliable joints. In industries like shipbuilding, construction, and heavy vehicle manufacturing, welded components need to withstand dynamic forces, vibrations, and impacts. Longteng carbon steel welding electrode E7016 ensures that the welds made using it maintain their integrity, even when subjected to rigorous conditions, providing long-lasting performance and reducing the risk of structural failure.

2. Excellent Impact Resistance

In addition to its tensile strength, Longteng carbon steel welding electrode E7016 offers excellent impact resistance, which is a crucial property in many industrial welding applications. With an impact energy of 170J at -30°C, the welds created with this electrode can withstand impact loads at lower temperatures, ensuring that structures remain intact even under challenging conditions such as cold weather or high-stress environments. This feature is particularly beneficial when welding structural components that will be exposed to vibration, shock, or sudden impacts. Whether it is in the construction of buildings, bridges, or transportation vehicles, the E7016 welding electrode ensures that the welded joints retain their strength and durability, reducing the likelihood of fractures or failures over time.

3. Superior Arc Stability and Smooth Finish

Longteng carbon steel welding electrode E7016 is coated with a specialized cellulose potassium coating that provides excellent arc stability and ensures smooth welding operations. The stable arc prevents spattering and minimizes weld defects, resulting in cleaner, more aesthetically pleasing welds. The coating also contributes to the weld's shielding, protecting it from atmospheric contaminants such as moisture, oxygen, and nitrogen, which could affect the integrity of the weld. Additionally, the E7016 welding electrode offers improved control over the welding process, which makes it easier to achieve uniform penetration and a high-quality finish. This characteristic is critical when welding components that must meet strict quality standards for appearance and performance, such as the frame structures of ships, bridges, and heavy-duty machinery.

4. Versatility and All-Position Welding

Another notable feature of the carbon steel welding electrode E7016 is its versatility. The "1" in the AWS classification indicates that this electrode is suitable for welding in all positions—flat, horizontal, vertical, and overhead. This makes it a highly flexible choice for a wide range of welding applications, including those that require welding in hard-to-reach or vertical areas. The versatility of the E7016 welding electrode allows welders to handle a variety of joint types and welding scenarios without compromising the quality of the weld. Whether it's a complex construction project or a large-scale shipbuilding operation, E7016 electrodes can be relied upon to deliver strong, durable welds across all welding positions.

Longteng carbon steel welding electrode E7016 is a powerful tool for welding carbon steel and low-alloy steel in demanding applications. With its high tensile strength, impact resistance, and ability to create smooth, stable welds, the E7016 welding electrode is ideal for use in industries such as shipbuilding, heavy machinery manufacturing, bridge construction, and general infrastructure development. Its superior mechanical properties, coupled with its versatility in welding all positions, make it an indispensable choice for creating strong, reliable welded joints that stand the test of time. For any heavy-duty welding operation, investing in high-quality carbon steel welding electrode E7016 ensures the durability and reliability of the welded components, contributing to the overall success and longevity of the project.

Email

Email