How Hot-Rolled Excavator Track Shoes Drive Reliability in Heavy Equipment Operations

2025-05-27

In the field of construction, mining, and heavy equipment operations, the reliability of each component plays a vital role in ensuring smooth and efficient functioning. One of the most crucial parts of an excavator's undercarriage system are the hot-rolled excavator track shoes, which enable the machinery to move efficiently across varied terrain while maintaining stability and traction. This article Longteng delves into the key benefits of hot-rolled excavator track shoes, their key characteristics, and why they are indispensable for maximizing performance in modern engineering machinery.

What Makes Hot-Rolled Excavator Track Shoes Essential for Heavy Machinery?

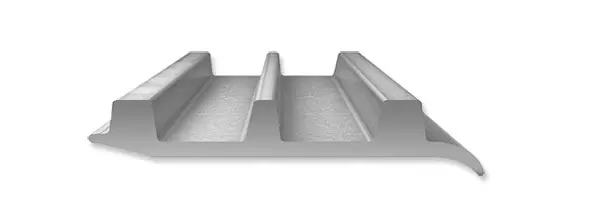

Excavator track shoes are part of the track system that directly interacts with the ground to provide the necessary support, traction, and movement for the machine. The hot-rolled excavator track shoe is specifically engineered to meet the demanding requirements of construction, mining, and other heavy-duty applications. These track shoes are manufactured using a hot-rolling process that involves heating steel to high temperatures and then rolling it into the desired shape. This technique enhances the properties of the material, providing improved strength, wear resistance, and durability.

The hot-rolling process contributes to the overall toughness and wear resistance of the track shoes, making them ideal for use in tough environments where normal track shoes would degrade much faster. In addition, these track shoes are designed to withstand extreme pressure, shock loads, and abrasive forces, ensuring that excavators can operate efficiently even in challenging conditions such as rocky, uneven, or slippery terrains.

The benefits of hot-rolled excavator track shoes extend far beyond simple traction, as they significantly affect the overall operational efficiency, safety, and lifespan of the machinery. When properly maintained, hot-rolled track shoes can provide consistent performance for longer periods, reducing downtime and increasing productivity.

Key Benefits of Hot-Rolled Excavator Track Shoes in Heavy Equipment Operations

1. Exceptional Durability and Wear Resistance

The durability of hot-rolled excavator track shoes is a standout feature that sets them apart from other types of track shoes. Hot-rolled steel is known for its increased strength and resistance to wear and tear. Excavators frequently work in harsh environments that subject the track shoes to constant friction, shock, and abrasion, especially in mining and construction sites where the ground can be rocky, uneven, and full of abrasive materials. Through the hot-rolling process, the steel is subjected to high heat and pressure, resulting in a stronger, more resilient product. This enhanced durability allows hot-rolled excavator track shoes to last longer, even under extreme operating conditions. The track shoes maintain their structural integrity over time, preventing premature wear and reducing the frequency of replacements, which can result in significant cost savings for companies.

2. Increased Traction and Stability

Excavators need to operate on various types of surfaces, and traction is one of the most critical factors in ensuring smooth movement. Hot-rolled excavator track shoes are specifically designed with optimal surface textures, such as cleats or grooves, to maximize grip and prevent slippage, even on slippery or uneven surfaces. This design ensures that the excavator can perform effectively across a wide range of environments, from muddy job sites to rocky, uneven terrains. The high strength of hot-rolled excavator track shoes contributes to greater stability during operation. Excavators often perform tasks such as lifting heavy materials or working on slopes, where maintaining balance is essential. Track shoes made of hot-rolled steel provide the necessary support to ensure that the machine remains stable under various load conditions, reducing the risk of tipping or losing control.

3. Enhanced Performance Under Extreme Conditions

Excavators operate in extreme environmental conditions, including high and low temperatures, moisture, and rugged terrain. The ability of hot-rolled excavator track shoes to perform in such environments is one of their most valuable characteristics. The high heat treatment involved in the manufacturing process helps the track shoes resist thermal fatigue, ensuring that they can operate in both hot and cold climates without experiencing significant wear or damage. The durability of these track shoes in extreme conditions extends to their performance in high-impact and heavy-duty environments. Whether working in quarries, construction sites, or mining operations, hot-rolled excavator track shoes deliver consistent performance without compromising their structural integrity, even when faced with abrasive and rocky conditions. The combination of strength, heat resistance, and wear resistance makes them ideal for high-performance applications.

Hot-rolled excavator track shoes are essential components in modern engineering machinery, offering durability, strength, and reliability in challenging environments. Their ability to withstand wear, provide superior traction, and perform effectively under extreme conditions makes them indispensable for industries such as construction, mining, and heavy lifting. By enhancing the performance and longevity of excavators, these track shoes play a critical role in improving operational efficiency and reducing downtime. Investing in high-quality hot-rolled excavator track shoes not only ensures smoother operations but also results in long-term cost savings, as they require fewer replacements and reduce maintenance needs. The robust and reliable nature of these track shoes ensures that excavators continue to perform optimally, helping companies achieve higher productivity and operational success.

Email

Email