Angle Section Steel for Shipbuilding: The Key to Strong, Durable, and Cost-Effective Ship Construction

2025-06-23

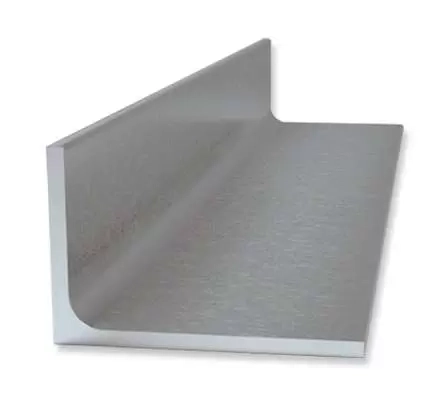

Angle section steel for shipbuilding, with its characteristic L-shaped cross-section, is an essential material in the construction of ships due to its strength, stability, and durability. This type of steel is widely used across various parts of a ship's structure, offering critical reinforcement in frames, decks, hulls, and superstructures. This article Longteng explores the benefits and key considerations when using angle section steel for shipbuilding, providing a comprehensive overview of its critical role in the industry.

Key Benefits of Angle Section Steel for Shipbuilding

High Strength-to-Weight Ratio

Angle section steel for shipbuilding is prized for its high strength-to-weight ratio. This means that despite its lightness, the material can support significant loads, making it essential in maintaining the balance between the weight of the ship and its structural strength. For any ship, minimizing weight is critical as excess weight can negatively affect the vessel’s buoyancy, fuel efficiency, and speed.

Angle section steel is typically used in the ship's structural frame, where the material’s lightweight nature ensures the ship maintains the necessary strength without exceeding weight limits. The high strength ensures that the framework and hull are sturdy and capable of handling the forces exerted on the ship during its operations. This balance is essential for shipbuilders to create vessels that perform efficiently in both calm and rough waters.

Additionally, the reduced weight means that ships built with angle section steel can carry more cargo, contributing to improved operational efficiency and profitability. Lighter ships consume less fuel, which reduces overall shipping costs and enhances the economic sustainability of the vessel.

Corrosion Resistance

Shipbuilding often involves constructing vessels that will face constant exposure to seawater, which is highly corrosive. Angle section steel for shipbuilding addresses this issue with its inherent corrosion resistance properties, particularly when treated with coatings or alloying elements. Stainless steel and galvanized versions of angle section steel are commonly used in shipbuilding for this very reason, as they can withstand the corrosive effects of saltwater over prolonged periods.

This corrosion resistance ensures that ships constructed with angle section steel remain structurally sound throughout their operational life, even when exposed to the harsh marine environment. The need for frequent maintenance is significantly reduced, as the steel will not degrade as quickly as untreated materials. This long-term durability minimizes the operational costs associated with repairs and increases the overall lifespan of the vessel.

By reducing the chances of rust and corrosion, angle section steel for shipbuilding also ensures that the ship remains safe, as corrosion could lead to structural failures, especially in critical areas such as the hull and frame.

Ease of Fabrication and Welding

Angle section steel for shipbuilding is easy to fabricate, cut, and weld. Its L-shape design is ideal for creating strong joints, which are vital for ensuring the ship’s structural integrity. Welding angle section steel allows for quick and efficient assembly of the ship's frame, and the material’s ease of manipulation makes it a highly adaptable option for shipbuilders.

During the construction of a ship, precise and custom fabrication is often required to ensure the ship fits specific design criteria. Angle section steel can be easily shaped to suit different needs, whether for the hull, deck supports, or internal reinforcements. This flexibility helps speed up the overall construction process, saving valuable time and reducing labor costs.

Moreover, the material's ease of welding makes it ideal for creating secure joints, especially in the areas that require additional strength, such as the hull or frame. The welding process also makes it simple to repair or modify sections of the ship as needed during the building process, ensuring the final product meets the required specifications.

Cost-Effectiveness

Angle section steel for shipbuilding is known for being a cost-effective material. Not only is it affordable compared to other high-strength materials, but its durability and corrosion resistance also reduce long-term maintenance costs. Shipbuilders can save significant amounts on repairs and replacements due to the material's resistance to rust, which helps ensure the vessel remains in service longer without major issues.

Additionally, angle section steel’s affordability is matched by its effectiveness in reducing operational costs. The material's lightweight nature helps improve fuel efficiency, as lighter vessels require less fuel to operate. This, in turn, enhances the ship's overall profitability, especially for commercial shipping companies that rely on the cost-effectiveness of their vessels to stay competitive.

Angle section steel is also easily sourced and readily available, ensuring that there are no significant delays in the procurement of materials during the shipbuilding process. This availability allows for quicker construction timelines, which can be critical in large-scale shipbuilding projects.

Selection Criteria for Angle Section Steel for Shipbuilding

Choosing the right type of angle section steel for shipbuilding is essential for ensuring the structural integrity, safety, and performance of the ship. Below are some of the most important criteria for selecting angle section steel for shipbuilding:

Material Grade

When selecting angle section steel for shipbuilding, the material grade plays a pivotal role in ensuring the ship’s long-term durability and structural integrity. Given the harsh marine environment, the steel must be able to withstand saltwater corrosion and environmental stress. For this reason, it’s essential to choose steel that offers superior resistance to corrosion, such as stainless steel or high-strength alloy steel. These materials provide excellent durability and are ideal for shipbuilding applications where exposure to the elements is constant. Selecting the right material grade ensures that the angle section steel for shipbuilding remains robust and reliable throughout the lifespan of the vessel. Additionally, factors like the grade's tensile strength and fatigue resistance should align with the operational conditions the ship will face, further ensuring safety and performance.

Dimensions and Weight

The dimensions and weight of angle section steel for shipbuilding are critical factors in the design and construction of a vessel. Steel dimensions, including the length, thickness, and profile, should be selected to meet the structural requirements of the ship, ensuring it can handle the various loads, stresses, and forces it will encounter during operation. The weight of the steel is another important consideration, as it should be optimized to avoid unnecessarily adding mass to the ship. Excess weight can impact the vessel's efficiency and fuel consumption. Therefore, it's essential to choose the appropriate size and thickness of angle section steel for shipbuilding based on the design specifications, balancing structural strength with weight efficiency to maintain optimal performance.

Corrosion Protection

In the marine environment, angle section steel for shipbuilding faces constant exposure to corrosive elements such as saltwater, humidity, and harsh weather conditions. As such, corrosion protection is an absolute necessity. To enhance the longevity and durability of the steel, it is commonly treated with corrosion-resistant coatings, such as galvanization, or made from inherently resistant materials like stainless steel. The treatment process forms a protective layer on the steel surface, preventing rust and degradation over time. For ships that will be operating in particularly harsh environments, additional protective measures may be required, such as advanced coatings or the use of corrosion-resistant alloys. The use of these treatments ensures that angle section steel for shipbuilding remains effective and reliable, even under constant exposure to saltwater and other corrosive elements.

Angle section steel for shipbuilding is an indispensable material due to its combination of strength, durability, corrosion resistance, and ease of fabrication. It is used in various parts of the ship, from the hull to the superstructure and machinery supports, contributing to the vessel's overall stability and longevity. By selecting the right angle section steel, shipbuilders can ensure that the ship remains reliable, cost-effective, and capable of performing in challenging maritime environments.

Email

Email